Capacity - 175 HP. Ribbon blender The stainless steel ribbon blender consists of a double layer design with an inside and outside blender fixed to the drive shaft to create thorough double-direction mixing with no dead spots.

DD 095 j.

. The agitator is designed as a double helical ribbon which allows to create convective movement of the materials in 2 directions achieving mixing of. Due to their popularity and many uses ribbon blenders today are offered by many vendors big and small. What is a ribbon blender.

1911enðer Fm61Q e Engineered plastic resins PesticÎdes and herbieides Epoxy resins Pet foods Bakery premixes Eye shadõw Pharmaceuticals PVC compoundiòg. IMCDP-1000 Ribbon Blender NO Part Name Photo Recommend QTY 1 Mixing Trough 1 PC 2 Gear box 1 PC 3 Motor 1 PC 4 cylinder 1PC 5 Emergency switch 1 PCS 6 Ribbon agitator 1 PC 7 Start button 1 PC 8 Stop button 1 PC 9 Discharge button 1 PC. Ribbon blenders are made of shell having a U shape in which is rotating an agitator.

Still a very simple and robust solution to mix dry materials. Areas mixing speed hygienic design ribbon blenders are. Ribbon mixers are very widespread in process industries for bulk.

The multi-purpose ribbon blender The classic ribbon blender is a familiar sight in production floors across the food beverage chemical pharmaceutical plastic agricultural and other industries. What is a ribbon blender. U-for Low to Medium volume Capacity single shaft.

The three impellers are shown in Figure 1 and are specified as follows. The ribbon blender is one of the most versatile and commonly used blender in the chemical pharmaceutical and food industries. However process conditions such as impeller operation near a liquid surface can impose severe mechanical loads.

Available in two shapes - U W. Good design and expert fabrication ensure fast repeatable mixing easy clean-up low maintenance and long service life. The flow field around three primary helical ribbon impellor configurations have been simulated using the SPH method.

Common ribbon blender processes. The butterfly valve is stainless steel manually operated and very reliable. According to reference 12 The ratio of the inner diameter of the container to the outer screw diameter is.

Usually a competent manufacturer of mixing equipment will take responsibility for the mechanical design. RIBBON BLENDER Mono block cGMP design SALIENT FEATURES. How ribbon blenders work Ribbon blenders consist of a U-shaped horizontal trough and an agitator made up of inner and outer helical ribbons that are pitched to move material axially in opposing directions and also radially.

Examples include ready-to-eat soups pasta sauces pet food and the like. Lets define some common processes and briefly discuss how the ribbon blender can be used for each. This combination promotes fast and thorough blending.

Batch size based on 65 of Blender volume. High-quality ribbon blenders feature tightly controlled clearances between the trough surfaces and agitator tips. Bearing mounted on lanterns outside of mixing container to avoid contamination.

2 the helical direction of the ribbon-screw is opposite and has a good axial flow effect. The ribbon blenders versatility for blending solids combined with it ability to perform heating cooling coating and other processes make it a very popular blender. Unique Mixers Furnaces Pvt LtdContact Person.

Model 42N-25 Ribbon Blender 25 cu. Lab blenders use the same effi cient agitator design as large production scale blenders. Need A Mixer Contact.

A Best Practices Guide Page 5 of 8 Preparing Solid-Liquid Suspensions. Mr Jayesh TekchandaneyEmail us. Designs exist which are over-performing ribbon blenders in some.

W-for Large to Mega volume Capacity double shaft. A single helical ribbon SHR with diameter d 130. Perhaps the most common ribbon blender operation.

Inlets Various inlets in the top cover allow for different. INTERNATIONAL MACHIINE CONCEPTS 10 10 Grid cover 1 PC 11 Shaft sealer 1PC 12 Bearing. Bearing mounted on lanterns out of mixing zone to avoid Cross.

The ability of this blender to handle solids of different size ranges bulk densities and other ingredient characteristics combined with the possibility of heating cooling drying and coating of solid particles makes its a very popular. All contact parts in stainless steel 316. We have built nearly 50 of these stainless steel jacketed and internal pressure.

Applications Ribbon blenders can be designed to operate in both batch and continuous modes. Batching dry ingredients is. Though mixer design begins with a focus on process requirements the mechanical design is essential for successful operation.

Ribbon Blenders are also utilized for mixing discrete solid pieces within a low-viscosity liquid vehicle. Due to its versatility and economy the ribbon blender is often the best choice for most mainstream blending applications. Model 42N-515 Ribbon Blender 515 cu.

Ribbon blenders can be customized to fit various appli-cations across a wide range of industries. The device adopts a ribbon-screw stirring system. Batch type blenders can be built up to capacities of 50 m3.

Performances of Dry solid powder mixing with in a twin Ribbon blade blender have been performed in this work in order to characterize mixing behavior in such a mixer of binary mixtures with different cohesionless materials. The effects of fill height and blade rotation speed on mixing homogeneity have been studied. As shown in FIG.

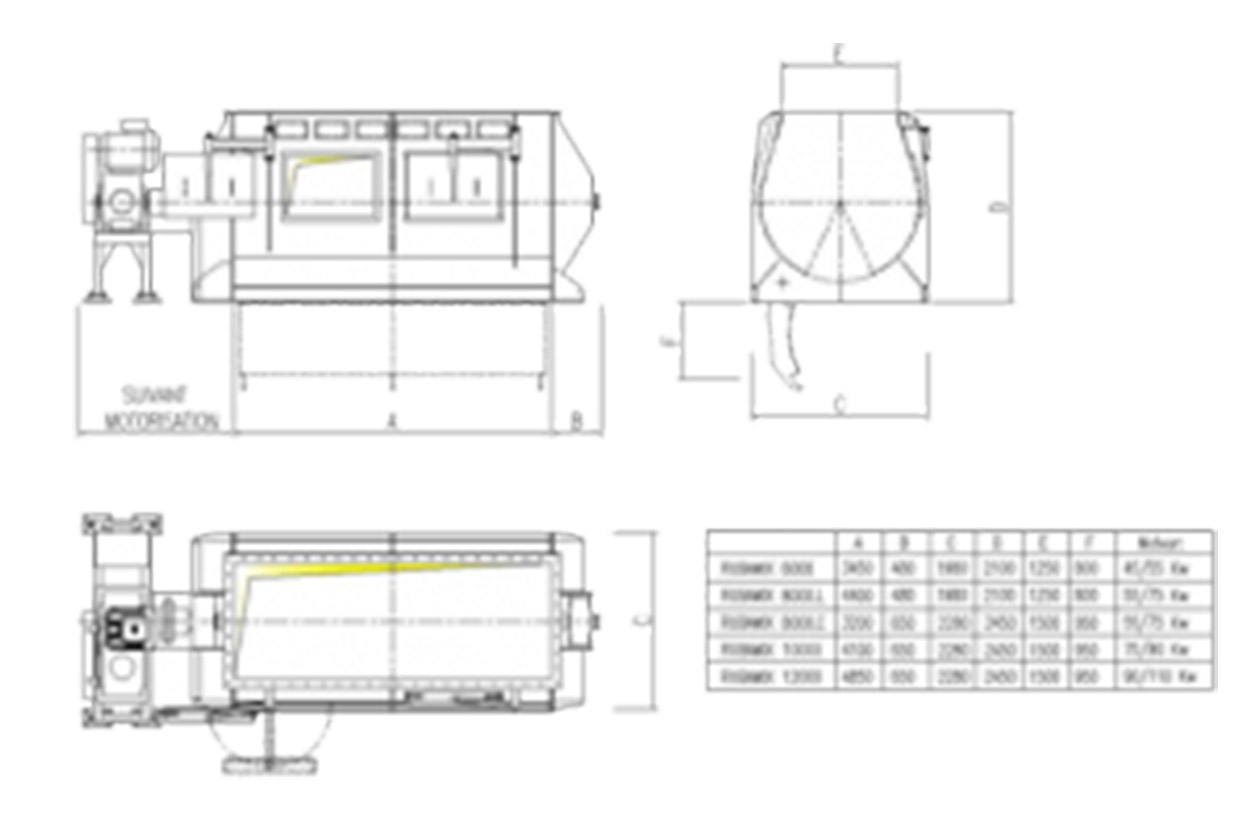

Specifying ribbon blenders. Available in two shapes - U W U-for Low to Medium volume Capacity single shaft W-for Large to Mega volume Capacity double shaft Batch size based on 65 of Blender volume All contact parts in SS 316L Designed to avoid Cross contamination with Monoblock Design Bearing mounted on lanterns out of mixing zone Air purge on the side entry. Ft 10 HPThis Ribbon Blender built in stainless steel and designed for center discharge is equipped with a control panel designed and built by Ross Systems Controls.

About of Ribbon Blenders Ribbon blenders are widely used for homogeneous mixing of dry granules powders. Benefits of ribbon blander Sanitary design-heavy gauge stainless steel constructions. Feeding through a hopper mounted on top of blender.

Ribbon blender design calculations pdf Ribbon paddle or paddle ribbon mixer combination design in mild or stainless steel with a variety of dischargers available Constructed with heavy-plate tub bottom and end plates A variety of drive assembly designs are available including shaft mount gear head or direct drive. Tip speeds in the range of 300 feetmin are typical. Design considerations had been studied during Analytical.

Calculation Double Helical Ribbon Pdf Pdf Viscosity Reynolds Number

Ribbon Blender Ribbon Mixer Design Calculation And Selection

Calculation Double Helical Ribbon Pdf Pdf Viscosity Reynolds Number

Ribbon Blender Ribbon Mixer Design Calculation And Selection

Ribbon Blender Ribbon Mixer Design Calculation And Selectionsparkler Filter Press Manufacturer

Ribbon Blender And Mixer Saintytec

Mixing Performance Of Ribbon Mixers Effects Of Operational Parameters Sciencedirect

0 comments

Post a Comment